In recent years, vertical packaging has emerged as a groundbreaking innovation in the packaging industry, transforming the way products are presented and preserved. According to packaging expert Dr. Emily Thompson, "Vertical packaging not only maximizes space efficiency but also enhances consumer engagement through its unique design." This shift in packaging methodology addresses modern consumers' demands for convenience and sustainability while ensuring that products stay fresh and visually appealing on the shelves.

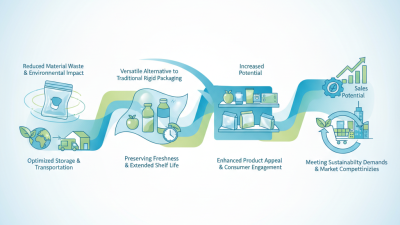

Vertical packaging techniques utilize an innovative approach that allows products to be packaged in a manner that minimizes material waste and optimizes storage capacity. By standing upright, these packages not only save space but also help brands stand out in a crowded marketplace. As the industry continues to evolve, vertical packaging is setting new standards for sustainability and aesthetics, making it a vital consideration for manufacturers and retailers alike looking to meet the changing needs of consumers.

As companies increasingly adopt vertical packaging solutions, the potential for revolutionizing the packaging landscape becomes more evident. This trend heralds a new era of efficiency, creativity, and environmental responsibility, positioning vertical packaging as a key driver of progress in the industry.

Vertical packaging is an innovative approach in the packaging industry, characterized by its upright design that optimizes space and enhances product visibility. This packaging method involves the use of vertical bags or pouches where products are efficiently packed from the top down. One of the key features of vertical packaging is its ability to accommodate a wide range of products, from snacks and powders to liquids and granulated items. This versatility makes it an attractive option for manufacturers, allowing them to tailor packaging solutions that meet specific product needs.

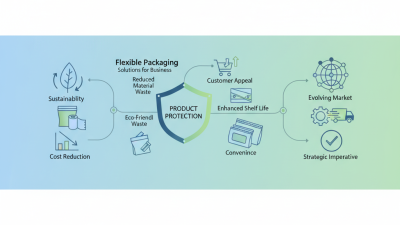

Another significant aspect of vertical packaging is its environmentally friendly nature. Many vertical packages are designed to use less material without compromising strength and protection, ultimately reducing waste. Additionally, they often utilize recyclable materials, contributing to sustainability efforts. The automation capabilities of vertical packaging machines also streamline the production process, increasing efficiency and reducing labor costs. As a result, vertical packaging not only captures consumer attention on the retail shelf but also aligns with modern sustainability goals, making it a transformative force in the packaging landscape today.

As the demand for efficient packaging solutions continues to grow, vertical packaging is emerging as a game-changer in the industry. This innovative approach leverages advanced technologies to streamline the packaging process, enhancing both productivity and sustainability. High-speed vertical form-fill-seal machines, equipped with precision sensors and smart automation, are at the forefront of this transformation. These systems not only increase production rates but also minimize material waste, promoting environmentally friendly practices.

Tip: When considering vertical packaging for your products, focus on the speed and efficiency of machinery to maximize output while reducing operational costs.

The advent of automation and data analytics has further propelled the evolution of vertical packaging. Smart technologies enable manufacturers to monitor their packaging lines in real time, allowing quick adjustments to optimize performance. This level of control enhances product consistency and quality, which is crucial in meeting the ever-evolving consumer demands.

Tip: Always stay updated with the latest technological trends in vertical packaging to ensure your business remains competitive and responsive to market changes.

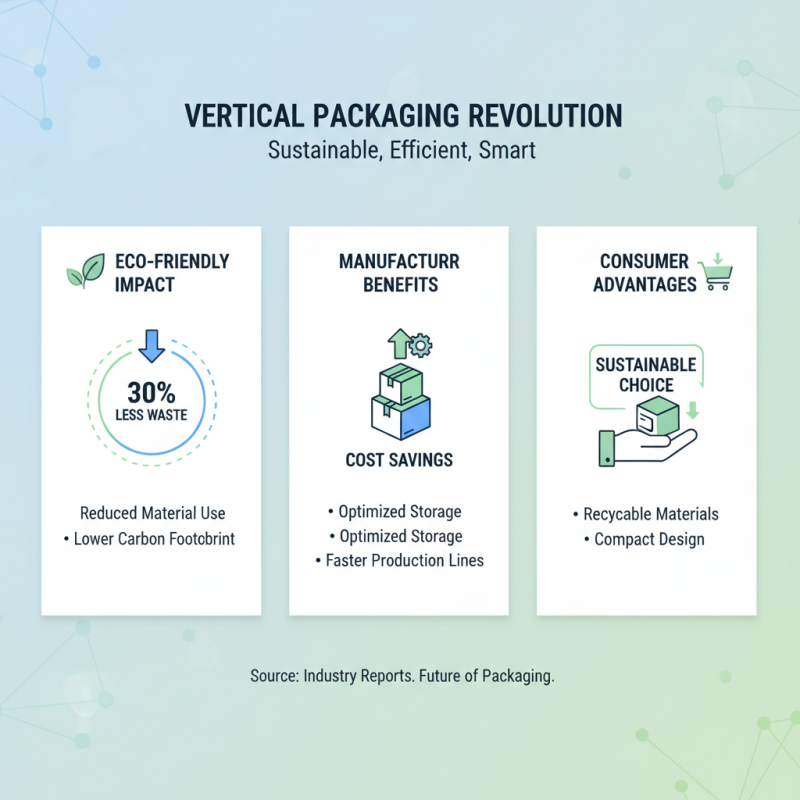

Vertical packaging is emerging as a transformative force in the packaging industry, offering a multitude of benefits for both manufacturers and consumers. According to recent industry reports, vertical packaging can significantly reduce packaging material waste by up to 30%. This reduction not only lowers production costs for manufacturers but also aligns with the increasing consumer demand for sustainable practices. As businesses seek to enhance their environmental responsibility, vertical packaging provides an efficient solution that minimizes the overall carbon footprint of packaging.

For consumers, the benefits of vertical packaging are equally compelling. This innovative packaging design often results in more space-efficient products, making them easier to store and handle. Studies indicate that vertical packaging can improve retail shelf space utilization by as much as 20%, allowing retailers to showcase more products while maintaining a clean and organized presentation. Additionally, the convenience of resealable features in vertical packages increases user-friendliness, enhancing the overall consumer experience. With efficiency, sustainability, and convenience at the forefront, vertical packaging is indeed revolutionizing the way products are presented and perceived in the market.

Vertical packaging technology has gained significant traction across various industries, driven by its efficiency and adaptability. The food sector, particularly, has seen remarkable enhancements in product preservation and shelf appeal through vertical packaging. According to a recent industry report, the global vertical packaging market is expected to reach $5.5 billion by 2027, growing at a CAGR of 4.6%. This growth is attributed to the demand for longer shelf life and reduced waste, which vertical packaging methods facilitate by providing an airtight seal and minimizing exposure to environmental factors.

In the pharmaceuticals industry, vertical packaging plays a crucial role in ensuring the integrity and safety of medical products. Case studies demonstrate that operations using vertical form-fill-seal machines have increased production speeds by 30%, allowing manufacturers to keep pace with rising regulatory requirements and consumer demands. Furthermore, electronics manufacturers are adopting vertical packaging to enhance durability and reduce material costs. The ability to design packages that occupy less space while maintaining structural integrity has proven economically advantageous, contributing to a projected 20% reduction in material costs across several case studies. These advancements illustrate how vertical packaging not only improves operational efficiency but also drives innovation across diverse sectors.

| Industry | Application | Benefits | Sustainability |

|---|---|---|---|

| Food & Beverage | Snack Foods | Extended shelf life, Reduced waste | Biodegradable materials |

| Cosmetics | Skincare Products | Elegant presentation, User-friendly | Recycled packaging options |

| Pharmaceuticals | Pill Packaging | Tamper-proof seals, Easy dispensing | Sustainable production processes |

| E-commerce | Shipping Supplies | Space-saving, Cost-effective | Minimalistic design, Reusable materials |

| Agriculture | Seed Packaging | Protection against pests, Improved storage | Compostable options available |

Vertical packaging is increasingly recognized for its potential to enhance sustainability within the packaging industry. By optimizing space and materials, vertical packaging minimizes waste and reduces the carbon footprint associated with transportation. This innovative approach allows brands to use fewer resources while maintaining product integrity, ultimately aligning with the global shift towards environmentally friendly practices. As companies adopt vertical packaging solutions, we are likely to see a significant decrease in excess material usage and energy consumption throughout the product lifecycle.

Tips for adopting vertical packaging sustainably include assessing the materials used in packaging and prioritizing recyclable or biodegradable options. Brands should also consider designing packages that maximize space efficiency during shipping and display, allowing for less void space and reducing the overall environmental impact. Collaborating with suppliers who share a commitment to sustainability can further enhance the positive effects of vertical packaging initiatives.

As the trend towards sustainability continues to grow, vertical packaging stands at the forefront, offering innovative and efficient solutions. The integration of eco-conscious practices in vertical packaging not only satisfies consumer demand for greener options but also supports long-term business viability. Embracing this evolution can drive meaningful change across industries while promoting a more sustainable future.