In today's competitive market, businesses are constantly seeking innovative solutions to enhance their product packaging. FFS (Form-Fill-Seal) packaging has emerged as a game-changing technology, offering substantial advantages across various industries. According to a report by Grand View Research, the global FFS packaging market is projected to reach USD 46.98 billion by 2025, driven by increasing demand for efficient and cost-effective packaging solutions. This growth reflects the industry's recognition of the array of benefits that FFS packaging provides.

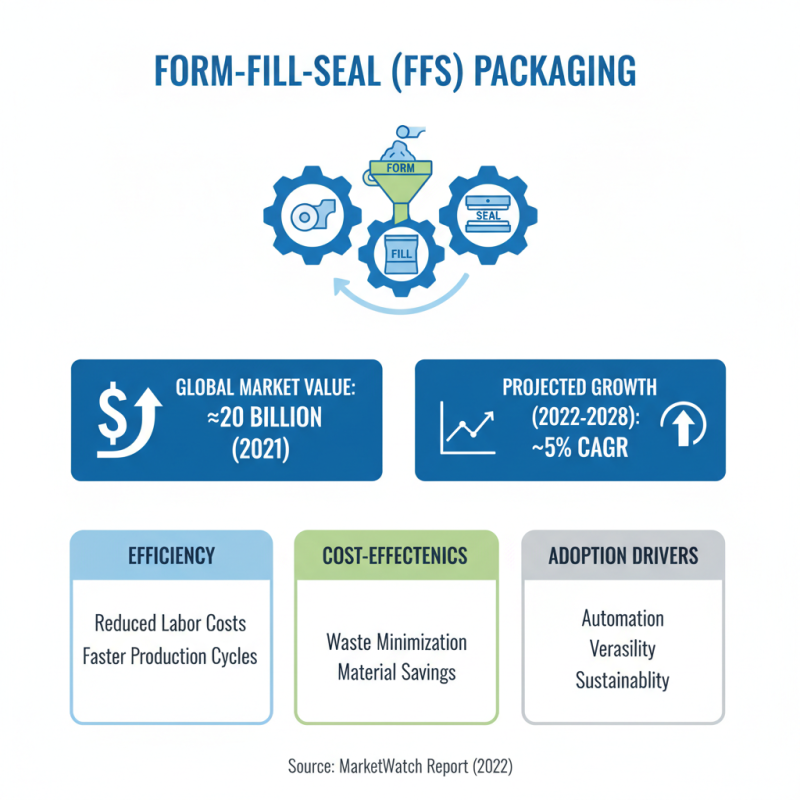

One of the standout benefits of FFS packaging is its ability to streamline the manufacturing process. By combining forming, filling, and sealing into a single operation, companies can significantly reduce labor costs and minimize packaging waste. A study published in Packaging Technology and Science highlights that FFS systems can lead to a 20-30% increase in operational efficiency, allowing businesses to allocate resources more effectively and improve their bottom line. Moreover, FFS packaging offers superior product protection, ensuring that goods remain fresh and uncontaminated, which is crucial in sectors such as food and pharmaceuticals.

As businesses aim to enhance sustainability practices, FFS packaging stands out by utilizing fewer materials while maintaining product integrity. This environmentally friendly approach is increasingly important as consumers are becoming more aware of sustainability issues. With the increasing push for reduced environmental impact, FFS packaging not only meets regulatory demands but also resonates with consumer preferences, ultimately leading to increased brand loyalty and market share. Embracing FFS packaging can thus be a strategic move for businesses aiming for long-term success.

Form-Fill-Seal (FFS) packaging represents a transformative approach to packaging solutions, particularly for businesses seeking efficiency and cost-effectiveness. FFS technology automates the packaging process by creating, filling, and sealing packages in a continuous operation. According to a report by MarketWatch, the global FFS packaging market was valued at approximately $20 billion in 2021 and is expected to grow at a CAGR of around 5% from 2022 to 2028. This rapid expansion highlights the increasing adoption of FFS processes by various sectors, driven by the demand for reduced labor costs, waste minimization, and faster production cycles.

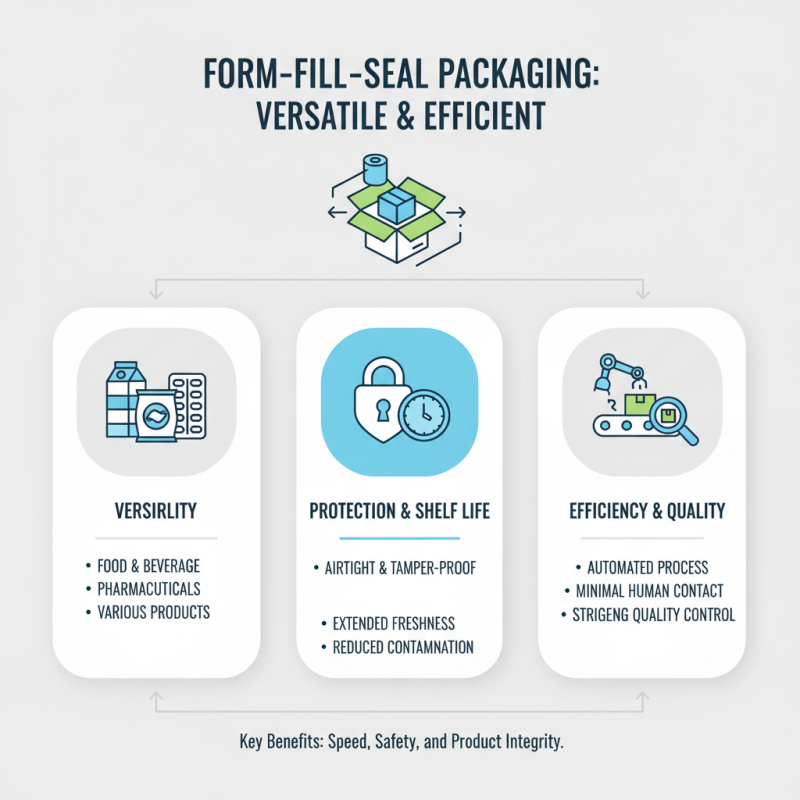

One of the key advantages of FFS packaging is its versatility. It can accommodate a wide range of products, from liquids to solids, making it ideal for industries such as food and beverage, pharmaceuticals, and personal care. A study by Smithers PIRA predicts that flexible packaging, which includes FFS, will account for nearly 50% of the total packaging market by 2025. Furthermore, FFS packaging ensures enhanced product protection and shelf life, thus yielding significant benefits in terms of quality and consumer satisfaction. These factors underscore the importance for businesses to consider FFS packaging as a viable solution to meet today’s competitive market demands.

Flexible film packaging (FFS) technology has revolutionized the way products are preserved and presented, particularly when it comes to enhancing freshness and extending shelf life. This innovative packaging method utilizes advanced films that create airtight seals around products, effectively preventing exposure to air and moisture that can lead to spoilage. As a result, businesses can maintain the quality and integrity of their goods, ensuring that consumers receive products at their freshest state.

In addition to preventing contamination, FFS technology employs barrier films that are specifically designed to resist environmental factors such as light, oxygen, and humidity. This means that products like foods, pharmaceuticals, and cosmetics can remain viable for longer periods, reducing waste and improving overall profitability. By investing in FFS packaging, companies not only enhance the customer experience with fresher products but also promote sustainability by minimizing the need for frequent restocking and disposal of spoiled goods.

Form-fill-seal (FFS) packaging has emerged as a game changer for many businesses, particularly in terms of cost-effectiveness. By automating the packaging process, FFS technology reduces labor costs associated with manual packing. This streamlined approach not only minimizes the need for additional workforce but also lowers operational overheads. Additionally, FFS packaging utilizes high-quality materials that are both lightweight and durable, resulting in reduced shipping costs and enhanced product protection.

Another significant cost-saving aspect of FFS packaging is its efficiency in material usage. The technology allows for precise measurement and dosing of packaging materials, which means less waste and more sustainable practices. Companies can also expect to benefit from shorter cycle times, enabling faster production and the ability to respond to market demands without incurring extra costs. With these advantages, businesses can allocate their resources more effectively, focusing on growth and innovation rather than excessive expenditure on traditional packaging methods.

Flexible Film System (FFS) packaging has emerged as a vital player in modern manufacturing, particularly due to its sustainability advantages. One of the primary benefits is the reduction of material waste. FFS technology allows for precise measurements of film, minimizing excess and ensuring that only the necessary amount of material is used. This leads not only to cost savings but also decreases the overall environmental impact associated with packaging production and disposal.

Furthermore, FFS packaging often employs recyclable materials, enhancing the circular economy principle. By utilizing materials that can be easily recycled or repurposed, manufacturers can significantly lessen landfill contributions and carbon footprints. Additionally, the lightweight nature of FFS packaging results in lower energy consumption during transportation, further supporting eco-friendly practices. As businesses increasingly prioritize sustainability, adopting FFS packaging can position them as forward-thinking leaders while also fulfilling consumer demand for greener alternatives.

Form-Fill-Seal (FFS) packaging is a versatile solution that caters to various industries, from food and beverage to pharmaceuticals. Its ability to efficiently produce packages that are airtight and tamper-proof makes it ideal for products that require extended shelf life and stringent quality control. For instance, in the food industry, FFS packaging allows for the preservation of freshness and flavor, extending the usability of perishable items. Additionally, its automated nature minimizes human contact, thereby reducing contamination risks.

Moreover, FFS packaging is not limited to a single sector; its adaptability extends to personal care, chemical, and pet food industries, among others. The technology enables the production of a wide range of package sizes and styles, meeting the specific needs of diverse products. By utilizing FFS packaging, businesses can enhance efficiency, reduce waste, and lower production costs, all while maintaining high-quality standards. This versatility makes FFS packaging an essential consideration for companies looking to optimize their packaging processes across multiple domains.