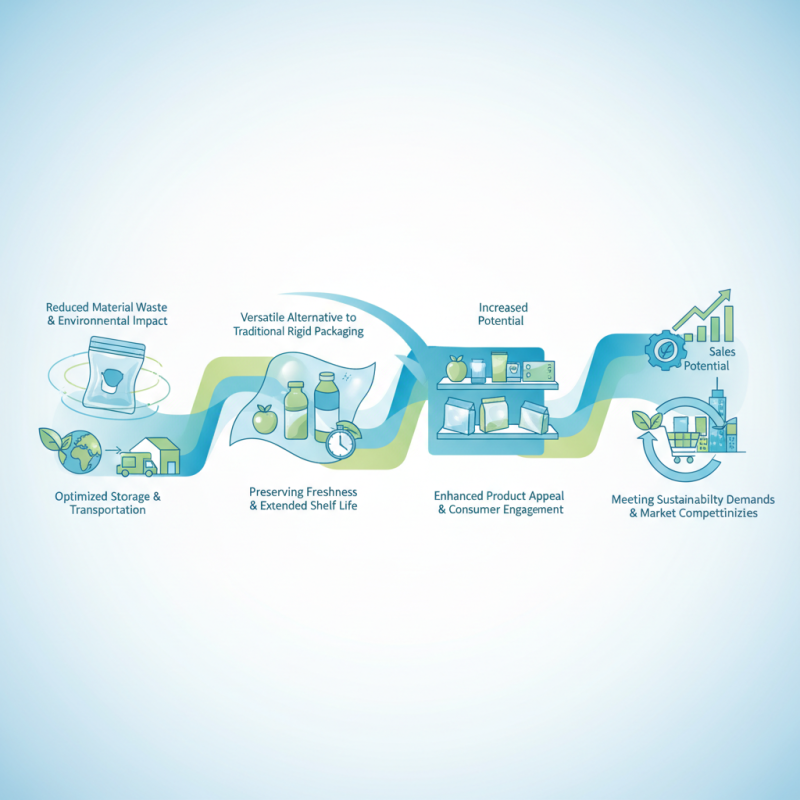

Flexible packaging solutions have emerged as a popular choice in the packaging industry, offering numerous advantages for businesses across various sectors. As companies seek innovative ways to enhance their product appeal while maintaining cost efficiency, flexible packaging solutions present a versatile alternative to traditional rigid packaging. These solutions are designed to adapt to the unique requirements of different products, whether it involves preserving freshness, extending shelf life, or improving logistical efficiency.

One of the key benefits of flexible packaging solutions is their ability to reduce material waste and environmental impact. By utilizing lightweight materials and innovative designs, businesses can minimize their carbon footprint while also optimizing storage and transportation costs. Furthermore, flexible packaging allows brands to create eye-catching designs that stand out on store shelves, enhancing consumer engagement and boosting sales potential. As the market evolves, adopting flexible packaging solutions becomes a strategic move for companies aiming to stay competitive and meet the sustainability demands of today’s consumers.

Flexible packaging refers to a type of packaging made from flexible materials that can easily change shape. This category encompasses a wide range of products, including pouches, bags, wraps, and films, which are often made from various combinations of plastics, paper, and sometimes aluminum. The versatility of flexible packaging allows it to conform to the product it contains while providing superior barrier properties. This means that flexible packaging can effectively protect contents from moisture, light, and oxygen, extending shelf life and maintaining product integrity.

One of the key advantages of flexible packaging is its lightweight nature, which not only reduces shipping costs but also minimizes space during transportation and storage. Furthermore, flexible packaging is often more sustainable than traditional rigid packaging, as it uses fewer materials and can be designed for recyclability or compostability.

Businesses can benefit from this adaptable solution through enhanced branding opportunities, as flexible packaging allows for vibrant graphics and easy customization. Additionally, it can streamline production processes, leading to cost savings and increased efficiency in operations. Overall, flexible packaging offers a modern approach that meets the evolving needs of both manufacturers and consumers.

Flexible packaging solutions encompass a variety of materials and formats that provide numerous benefits for businesses across various sectors. One of the most common types is stand-up pouches, which are popular for their durability and shelf appeal. They are designed to stand upright on shelves and come in various sizes and closure options, making them ideal for both food and non-food products. Their lightweight nature reduces shipping costs, and they often use less material than traditional rigid packaging, aligning with sustainability goals.

Another prominent type of flexible packaging is stretch films, which are widely used for bundling products together and ensuring stability during transport. These films cling to the surfaces of the products, providing protection against dust and moisture while optimizing storage space. Additionally, shrink films are utilized in the packaging of items that require a tight seal, conforming closely to the shape of the product once heat is applied. This versatility in application makes flexible packaging solutions not only efficient but also economically favorable for businesses aiming to enhance their product presentation and reduce waste.

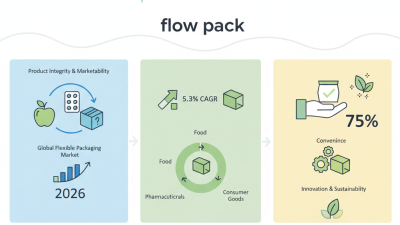

Flexible packaging has become an essential solution for businesses looking to optimize their product presentation while ensuring functional efficiency. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.3%. This growth indicates a rising trend as businesses recognize the multifaceted benefits that flexible packaging offers, ultimately driving product appeal and reducing costs.

One of the key advantages of flexible packaging is its ability to enhance shelf life and reduce waste. Flexible materials are often more effective at protecting products from light, oxygen, and moisture compared to rigid packaging. Research indicates that packaging innovations can reduce food waste by up to 15%, which not only saves money but also contributes to sustainability efforts. Additionally, flexible packaging provides significant weight advantages, leading to lower shipping costs and reduced environmental impact due to less fuel consumption during transport.

Furthermore, the versatility of flexible packaging allows for customization and branding opportunities that can attract consumers. The ability to use vibrant prints and various formats enables businesses to stand out in a competitive market. Industry insights reveal that products in flexible packaging can see a sales increase of up to 20% compared to those in traditional packaging. This highlights the importance of investing in flexible packaging as a strategy for enhanced market presence and profitability.

| Advantage | Description | Impact on Business |

|---|---|---|

| Cost-Effectiveness | Flexible packaging often requires less material and can be produced at a lower cost. | Reduced packaging expenses allow for better profit margins. |

| Lightweight | Flexible packaging is lighter than rigid options, leading to lower shipping costs. | Helps in reducing overall logistics costs. |

| Versatility | Can be used for various products, including food, pharmaceuticals, and consumer goods. | Flexibility in production can cater to diverse markets. |

| Sustainability | Often made from recyclable or biodegradable materials, contributing to environmental goals. | Enhances brand reputation among environmentally conscious consumers. |

| Customizability | Flexible packaging solutions can be tailored in size, shape, and design to fit specific needs. | Allows for unique branding opportunities that can distinguish products in the market. |

Flexible packaging solutions are designed to enhance the shelf life and safety of various products, making them an ideal choice for businesses looking to preserve quality and reduce waste. One of the primary features of flexible packaging is its ability to create a hermetic seal, thus preventing the entry of air and moisture that can lead to spoilage. This seal is crucial for foods, pharmaceuticals, and other perishable items, as it extends their usability and retains freshness for longer periods, contributing to reduced spoilage rates.

Moreover, the lightweight nature of flexible packaging not only minimizes transportation costs but also enhances product safety through durable materials that protect against physical damage. Through innovative designs, flexible packaging can include barrier properties tailored to specific needs, such as UV protection or tamper-evident features, which are vital for maintaining product integrity. This flexibility allows businesses to ensure that their products remain safe for consumers while also complying with safety regulations. By incorporating flexible packaging solutions, companies can significantly increase their operational efficiency and consumer trust, ultimately fostering a stronger market presence.

Implementing flexible packaging can offer significant advantages for businesses across various sectors. However, it also requires careful consideration of several factors to ensure successful execution. One of the primary aspects to assess is the material compatibility with the product being packaged. According to a report by Smithers Pira, the flexible packaging market is expected to reach $267 billion by 2024, highlighting a growing trend in this direction. Businesses must evaluate whether their products will maintain quality and safety using these materials, particularly in food, pharmaceuticals, and other sensitive industries.

Economic factors should also play a crucial role in decision-making. Flexible packaging typically reduces shipping costs due to its lightweight nature and offers extensive design opportunities, allowing brands to stand out on the shelf. A study by Freedonia Group indicates that flexible packaging can reduce material usage by up to 30% compared to rigid alternatives, translating to cost savings and reduced environmental impact. When considering a shift to flexible packaging, businesses should calculate long-term savings and compare them against initial investment costs.

Tips:

1. Assess your supply chain capabilities to accommodate new flexible packaging formats.

2. Conduct market research to understand consumer preferences for sustainability in packaging.

3. Collaborate with packaging suppliers to explore innovative materials and designs that align with your brand values.