Choosing the right vertical baggers for your lawn care or landscaping needs can be a daunting task, especially with the myriad of options available on the market today. Vertical baggers are essential tools for efficiently collecting grass clippings, leaves, and other debris, making lawn maintenance easier and more effective. When selecting a vertical bagger, understanding your specific requirements and the features that these machines offer can significantly enhance your gardening experience.

This guide aims to provide you with the top 10 essential tips for choosing the best vertical baggers tailored to your needs. From evaluating the size and capacity of the bagger to considering the ease of use and maintenance, each aspect plays a critical role in ensuring that you make an informed decision. By keeping these key points in mind, you will be well-equipped to select the perfect vertical bagger that not only meets your demands but also delivers outstanding performance, helping you achieve a pristine, well-manicured lawn with minimal effort.

When selecting the best vertical bagger for your needs, it is crucial to understand the fundamentals that dictate their functionality and suitability. First, consider the type of materials you will be working with. Different vertical baggers are designed to accommodate various bag sizes and textures, so identifying the specific requirements of your product is vital. For instance, heavier materials may require a more robust machine with enhanced sealing capabilities to ensure that the bags remain intact during transport and storage.

Another key factor to consider is the machine’s ease of use and adjustability. A user-friendly interface can significantly streamline operations, reducing downtime and the learning curve for new operators. Look for models that offer quick adjustments for different bag sizes or styles, as this flexibility can significantly enhance productivity. Additionally, assess the maintenance needs of the equipment; easier maintenance will not only prolong the lifespan of the machine but also ensure optimal performance in the long run. By focusing on these essential elements, you can make an informed decision that meets your vertical bagging needs effectively.

When selecting vertical baggers, several key features should be taken into account to ensure you choose the best fit for your needs.

One crucial aspect is the size and capacity of the bagger. Assess your typical workload to determine the optimal size that will allow for efficient operation without constant bag changes.

Additionally, baggers with adjustable height settings can enhance ergonomics, making them easier to use for operators of different statures.

Another important feature is the speed and efficiency of the bagging process. Look for models that offer adjustable speed settings,

which allow for flexibility depending on the material being bagged. This can save you significant time and labor costs.

Furthermore, consider the ease of maintenance; baggers that are designed for quick disassembly and cleaning will save you time and extend the lifespan of the equipment.

Lastly, think about the level of automation you need.

Semi-automatic models can provide a good balance between control and efficiency, while fully automatic options may be beneficial for high-volume operations.

Exploring these features and understanding your specific requirements will ensure you make an informed decision when choosing the perfect vertical bagger for your business.

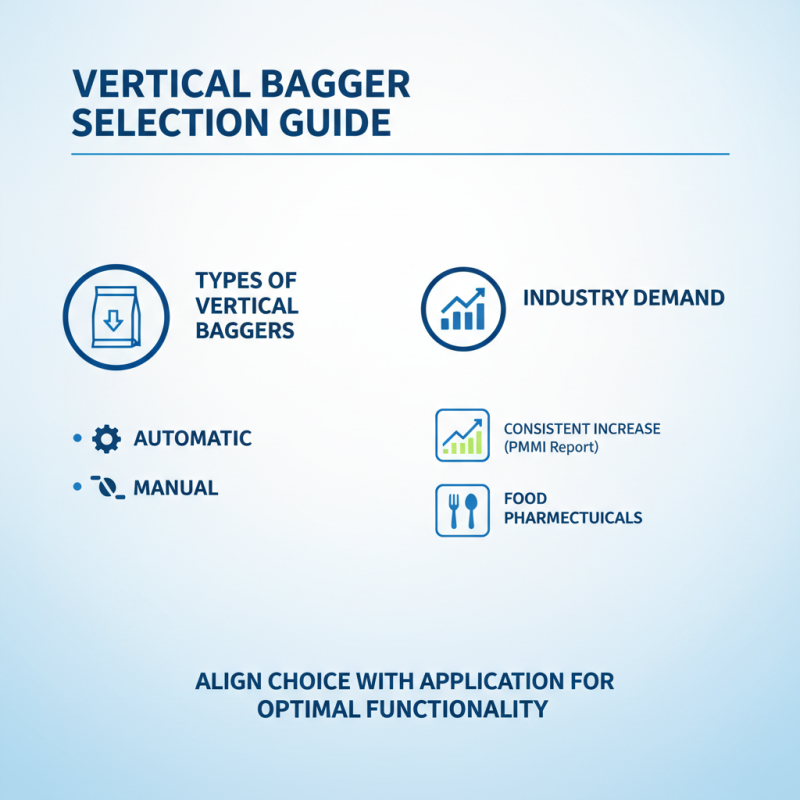

When selecting a vertical bagger, understanding the various types available is crucial to meet your specific needs. Vertical baggers come in different configurations, such as automatic and manual models, each designed to handle various bagging tasks. According to a report from the Packaging Machinery Manufacturers Institute, the demand for vertical baggers has seen a consistent increase, driven by the growing need for efficient packaging solutions across industries such as food processing and pharmaceuticals. This highlights the importance of aligning your choice with the intended application to ensure optimal functionality.

Tip 1: Evaluate your production speed requirements before choosing a model. Higher-speed machines can significantly enhance efficiency in busy production environments, but they may come with a steeper investment.

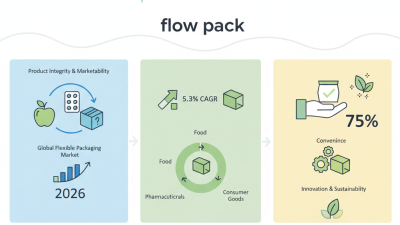

Additionally, consider the types of materials you'll be bagging. Some vertical baggers are engineered for specific materials, such as powders, granules, or liquids, each requiring distinct features for effective handling. A study by the Food Packaging Forum indicates that utilizing suitable bagging machinery can reduce waste by up to 30%, which underscores the necessity of matching equipment to your material's characteristics.

Tip 2: Make certain to assess the size and type of bags that the machine can accommodate. Compatibility with various bag sizes can offer greater flexibility and efficiency, particularly if your production line deals with diverse packaging needs.

When it comes to selecting the ideal vertical bagger for your needs, evaluating brand reputation and customer reviews is crucial. A trustworthy brand usually has a history of providing reliable products. Take the time to research various manufacturers, focusing on their longevity in the industry and any awards or recognitions they may have received. This background can provide insight into their commitment to quality and innovation.

Customer reviews are another essential aspect to consider. They offer real-world experiences that can help you identify any potential issues with a product. Look for feedback that highlights durability, ease of use, and efficiency. Reading various reviews can help differentiate between genuine complaints and isolated incidents. Additionally, pay attention to how brands respond to customer feedback, as this reflects their dedication to satisfaction and improvement.

When evaluating vertical baggers, it is wise to compare specifications such as power, bag capacity, and ease of maintenance. It's beneficial to test different models in-store, if possible, to find one that feels comfortable and suits your gardening needs. Remember, selecting the right vertical bagger is not just about the features but also about aligning those features with your specific gardening requirements.

When it comes to selecting vertical baggers, budgeting plays a crucial role in ensuring that you get the best value for your investment. Start by establishing a clear budget that reflects your specific needs and intended use. Consider the features that are essential for your operation—like capacity, efficiency, and durability—without overspending on unnecessary extras. Research various models thoroughly and compare their specifications to identify those that fit within your financial limits.

Additionally, look for promotions, discounts, and financing options that can help alleviate the immediate financial burden. Buying refurbished or gently used vertical baggers can also be a viable path to saving money while acquiring a high-quality machine. Remember that effective performance does not always come with a hefty price tag; with careful planning and research, it is possible to find affordable yet efficient equipment that meets your operational requirements without compromising on quality.