Choosing the right flow pack packaging for your products is crucial for maintaining product integrity and enhancing marketability. As the global flexible packaging market is projected to reach over $300 billion by 2026, driven primarily by the demand for innovative and sustainable packaging solutions, understanding the nuances of flow pack packaging becomes essential for businesses aiming to remain competitive. According to a recent report by Smithers Pira, the demand for flow pack packaging is expected to grow at a CAGR of around 5.3% over the next five years, reflecting a shift toward more efficient and user-friendly packaging formats across various sectors.

Flow pack packaging, known for its ability to provide a tight seal and extend shelf life, serves multiple industries such as food, pharmaceuticals, and consumer goods. The versatility of flow pack technology allows for customized designs that cater to specific product requirements while optimizing production processes. A study indicates that nearly 75% of consumers prefer products in well-packaged formats that enhance convenience and preserve freshness. Therefore, comprehensively assessing the features and benefits of flow pack packaging is indispensable for manufacturers looking to attract consumers and ensure their products stand out in a crowded marketplace.

Flow pack packaging is a form of flexible packaging that creates a sealed package by folding and sealing plastic films around products. This type of packaging is particularly beneficial for items that require protection from moisture, dust, and contamination. With its ability to conform closely to the product shape, flow pack packaging maximizes shelf life while presenting an attractive appearance to consumers.

One major advantage of flow pack packaging is its efficiency in high-speed production lines. It allows for quick packaging of various products, which can significantly streamline operations and reduce costs. Additionally, this type of packaging is customizable, offering options like transparent windows to enhance product visibility, as well as options for adding perforations for easy opening.

**Tips:** When choosing flow pack packaging, consider the specific protective needs of your product, including moisture resistance and barrier properties. Always evaluate the aesthetics of the packaging to ensure it aligns with your brand image. Finally, remember to assess the environmental impact of the materials you choose, as sustainable packaging solutions are becoming increasingly important to consumers.

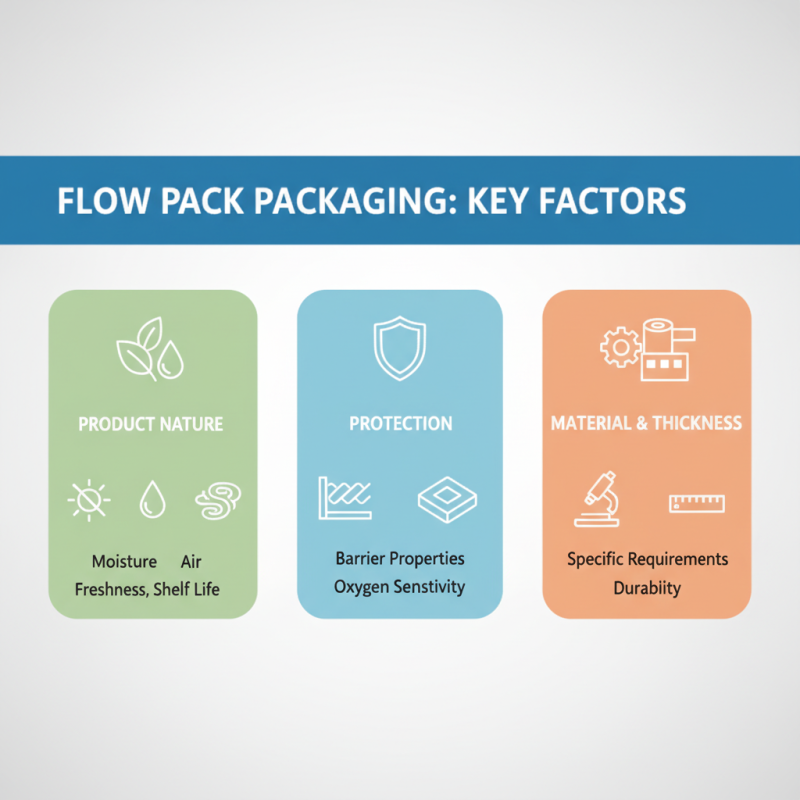

When selecting the ideal flow pack packaging for your products, several key factors come into play. Firstly, consider the nature of the product itself. The packaging must effectively protect the product from external elements such as moisture, light, and air, which can all impact freshness and shelf life. Products that are perishable or sensitive to oxygen will require barriers that can maintain their quality over time. Therefore, understanding the specific requirements of your product is crucial in determining the appropriate material and thickness for the packaging.

Another important aspect to evaluate is the production speed and efficiency. Flow pack packaging should align with your manufacturing process to ensure that it can keep up with demand without causing bottlenecks. Assessing the machinery available for packaging and any necessary modifications is essential. Additionally, consider sustainability factors, as consumers are becoming increasingly aware of environmental impacts. Choosing recyclable or biodegradable materials can enhance your brand’s appeal and meet customer expectations for environmentally responsible practices. By focusing on these key considerations, you can select the best flow pack packaging that meets both product requirements and market demands.

Flow pack packaging is a popular choice among manufacturers for its versatility and efficiency in sealing products. The materials used in flow pack packaging play a crucial role in determining the effectiveness of the packaging in preserving product freshness, extending shelf life, and ensuring durability during transportation and display.

Commonly used materials include polypropylene (PP), polyethylene (PE), and polyester (PET), each offering unique properties suited for different types of products.

Polypropylene is favored for its excellent clarity and strength, making it an ideal option for packaging food items that require visibility for marketing purposes. Its barrier properties also help protect against moisture, enhancing the product's longevity.

Polyethylene, on the other hand, is valued for its flexibility and durability, often used for packaging items that need to endure rough handling. It provides a reliable seal that helps keep products secure, while also being cost-effective. Lastly, polyester offers good moisture and oxygen barrier properties, making it suitable for products that are sensitive to environmental exposure, such as snacks and dried goods.

By understanding the characteristics of these materials, businesses can make informed decisions on the best flow pack packaging options tailored to their products’ specific needs. The right material not only enhances product protection but also contributes to the overall aesthetic appeal, potentially affecting consumer purchasing decisions.

When selecting flow pack packaging for your products, customization options play a crucial role in enhancing both functionality and brand identity. These packages can be tailored to meet specific dimensions, ensuring a perfect fit for your items, which not only improves protection during transport but also maximizes shelf space. Additionally, incorporating personalized features such as perforations or tear notches can enhance user experience, making it easier for consumers to access the product while ensuring the packaging remains intact until it is opened.

The aesthetic appeal of flow pack packaging is also greatly influenced by customization. Businesses can choose from a variety of materials, finishes, and colors to create a visually striking package that aligns with their branding strategy. Advanced printing techniques, including digital and flexographic printing, allow for vibrant graphics and intricate designs that can make a product stand out on the shelf. Furthermore, sustainable materials and eco-friendly options can be integrated into the design, appealing to environmentally conscious consumers while reinforcing a company's commitment to sustainability.

Sustainability considerations are becoming increasingly important in the choice of flow pack packaging for various products. With more consumers recognizing the environmental impact of packaging waste, manufacturers are under pressure to adopt eco-friendly materials. According to a recent report from Smithers Pira, the global market for sustainable packaging is projected to reach $500 billion by 2025, highlighting a significant shift toward environmentally responsible practices in the industry.

When selecting flow pack packaging, it's crucial to prioritize materials that are recyclable, biodegradable, or made from renewable resources. For instance, using polyethylene films that can be easily recycled can significantly reduce landfill waste. Additionally, incorporating plant-based plastics, like PLA (polylactic acid), is a practical alternative that not only diminishes carbon footprint but also appeals to eco-conscious consumers. A study from the Environmental Packaging Alliance noted that 73% of consumers are willing to pay more for products with sustainable packaging, indicating a market demand that businesses cannot afford to ignore.

Tips for choosing sustainable flow pack packaging include evaluating the lifecycle of your packaging materials to understand their environmental impact, exploring partnerships with suppliers who prioritize sustainable practices, and engaging consumers with transparent information about your choices. By integrating sustainability into your packaging strategy, you not only contribute to environmental health but also enhance your brand's reputation in a competitive market.