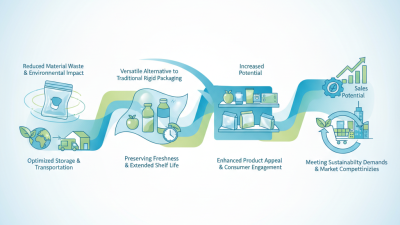

In today’s competitive market, flexible packaging solutions are gaining significant traction. According to Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2024. This growth highlights the increasing preference for adaptable packaging that meets diverse business needs. Flexible packaging is lightweight, which helps reduce shipping costs. Its versatility allows it to accommodate various product forms, from liquids to solids.

Moreover, brands benefit from enhanced shelf appeal. Research indicates that products with flexible packaging can see a 12% higher shelf visibility compared to rigid counterparts. However, challenges remain. Some businesses may struggle with quality control or finding the right material mix. Balancing adaptability and durability can be tricky. While embracing flexible packaging solutions may seem daunting, the long-term advantages can outweigh short-term uncertainties. Adopting these solutions can lead to cost savings and greater customer satisfaction.

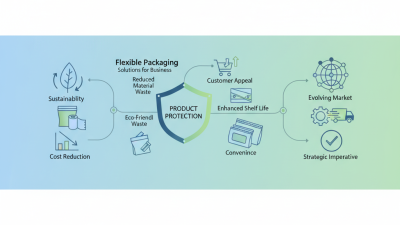

Flexible packaging is becoming a popular choice for many businesses. It offers numerous benefits, especially in cost-effectiveness. For instance, flexible materials like pouches and films typically use less raw material than rigid packaging. This reduction lowers production costs, making it easier for companies to save money.

In the fast-paced market, time is critical. Flexible packaging can streamline the production process. It often requires less energy for production and transportation, further decreasing overall expenses. Additionally, this type of packaging is lightweight, which can reduce shipping costs significantly. However, it’s essential for businesses to consider the balance between cost and quality.

Despite its advantages, some challenges exist. Not every company might have the infrastructure to adopt flexible solutions seamlessly. There may be initial setup costs that can strain budgets. Moreover, flexible packaging may not always provide the same level of protection as rigid packaging. Evaluating these factors is crucial to making the right choice for your business needs.

Flexible packaging offers unique benefits for businesses while positively impacting the environment. One significant advantage is its ability to reduce waste. Traditional packaging often leads to a lot of excess material. In contrast, flexible packaging uses fewer resources. This means less material in landfills and a focus on sustainability.

The carbon footprint associated with flexible packaging is notably lower. These materials are lighter, which reduces transportation emissions. They are designed to keep products fresh, extending their shelf life and minimizing spoilage. However, not all flexible packaging options are ideal. Some may not be recyclable or compostable, necessitating careful selection by businesses.

As we explore flexible packaging, we must reflect on our choices. Is the convenience worth the potential environmental cost? Families are increasingly mindful of sustainability. Companies face pressure to adapt. The relationship between packaging and an environmental impact is complex, and continuous improvement is needed. Embracing flexible packaging can lead to a more sustainable future, but it requires ongoing effort and consideration.

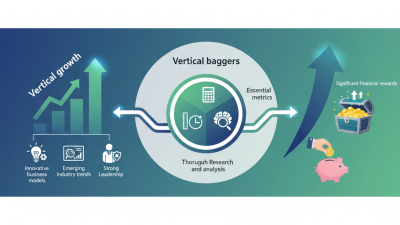

The flexible packaging market is experiencing rapid growth. According to recent studies, it is projected to reach $500 billion by 2028. This rise is driven by various industries seeking sustainable and efficient packaging solutions. Flexible packaging offers advantages like reduced waste and lower shipping costs.

Food and beverage sectors are significant drivers. About 55% of the flexible packaging market is attributed to these industries. Consumers demand fresher products with longer shelf lives. Flexible packaging meets this need by preserving quality and extending the product lifespan. However, maintaining quality control during production remains a challenge.

The healthcare industry is also adopting flexible packaging. A report indicates that the use of flexible materials in medical devices is expected to rise by 10% annually. This trend highlights the need for packaging that ensures safety and compliance. Yet, companies must be cautious. Meeting regulatory standards while innovating can be difficult. Balancing efficiency, sustainability, and safety requires constant reflection and adaptation.

Flexible packaging solutions offer great customizability for various products. Tailoring packaging to individual needs can enhance product visibility and safety. From shapes to materials, every detail can be adjusted. This flexibility allows businesses to showcase their unique branding while meeting specific requirements.

Tips: Consider the product’s shelf life. Some materials preserve freshness better than others. Also, think about consumer convenience. Easy-to-open packaging can improve user experience.

Customization can also lead to challenges. Balancing costs with quality is crucial. Overly complex designs may confuse suppliers or inflate production time. It's important to evaluate different options to find the most effective solution for your products. Listen to consumer feedback, and refine your approach as needed.

| Packaging Type | Material Used | Customization Options | Suitable Products | Estimated Cost (per unit) |

|---|---|---|---|---|

| Stand-up Pouch | PET/PE | Size, Color, Print | Snacks, Pet Food, Powdered Products | $0.25 |

| Flat Bags | LDPE | Size, Thickness, Print | Clothing, Accessories | $0.15 |

| Roll Stock Film | BOPP | Length, Width, Custom Prints | Ready Meals, Frozen Foods | $0.20 |

| Boxed Packaging | Recycled Cardboard | Shape, Print, Inserts | Electronics, Gifts | $1.00 |

| Sleeve Packaging | PVC | Custom Shape, Print | Bottles, Cans | $0.30 |

When evaluating flexible packaging solutions, shelf life and protection stand out as key performance metrics. Flexible packaging often offers superior sealing properties, which can significantly extend the freshness of products. This means less food waste and happier customers. For example, snacks packaged in flexible pouches often remain crispy longer than those in rigid containers. This can be a game-changer for businesses aiming to minimize loss.

However, it is essential to consider the environmental impact. Some flexible materials are non-recyclable, creating a dilemma for eco-conscious brands. This aspect can lead to challenging decisions about sustainability versus product longevity. While flexible solutions make products last longer, the trade-offs can be substantial.

Rigid packaging, on the other hand, provides robust protection against physical damage. Glass jars can endure tough handling, a plus for fragile items. Yet, they may not match the shelf life of flexible options. Moreover, the weight and bulkiness of rigid packaging can increase transportation costs. Each type has merits, but choosing the best requires careful balancing of performance with practical limits and values.